COMPOSITEC: Automotive battery pack housings made of Biobased composites

COMPOSITEC is participating in the BIOntier project as the lead for Use Case No. 3 (UC3).

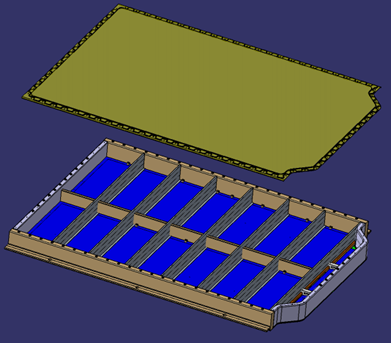

In this use case, an automotive battery housing is developed with thermoplastic bio-composite, replacing an element normally made of steel, aluminum or glass fiber reinforced thermoset composites.

This UC concentrates on three distinct parts: (1) a small housing with a complex molded shape, (2) a large top cover, and (3) a base plate demonstrator.

Battery housing top covers in Battery Electric Vehicles (BEV) are essential for enclosing battery modules and protecting individual cells. These components must possess structural integrity, resist thermal runaway events (including explosions and resultant fires), and ensure liquid and air tightness.

A unique BioC will be tailored to deliver enhanced mechanical properties, temperature resistance and flame retardance. The BioC will be designed to withstand moisture load, and accommodate subsequent thermocompression molding process. Additionally, it will be fully recyclable, aligning with sustainability goals.

Materials used to manufacture top covers are mainly steel, aluminium or composite (SMC, i.e. a combination of unsatured polyester, chopped glass fibers, mineral fillers, and additives). The main functions of the top cover are

Tighness (ensure tightness of the battery pack, i.e., full protection against dust-tight, protection against full water immersion, and close-range, high-pressure water jets).

Protection of the car occupants againts fire in case of a thermal runaway of the batteries during a given amount of time.

Electromagnetic shielding.

Sufficient mechanical resistance (to resist all cases happening during the lifetime of the car from manufacturing to end of life). The mechanical requirements are not very high because the part is between the batteries and the floorpan of the car body in white.

Resistance to underbody environment during the car lifetime

In BIONTIER, two top cover will developed using existing prototype molds. Both parts are in production today by COMPOSITEC and the two parts are molded with SMC by compression molding. The “small” top cover has a dimension of 700 x 400 x 200 mm and weighs around 3 kg. It is assembled on the battery pack of an electric scooter. The “large” battery pack has a dimension of 2000 x 1100 x 250 mm and weighs around 10 kg. The targeted properties of the BioC developed in BIONTIER should therefore be similar to the reference SMC material, have a cost premium that is acceptable, and have a better sustainability than the reference material.

The two top covers are developed by COMPOSITEC in collaboration with FRAUNHOFER for the material composition and the molding process.

The work is currently focusing on the following materials

Thermoplastic: PA11 or biobased PP

Fibers: flax fabrics and flax or hemp mats

COMPOSITEC is developing semi-products as organo sheets and GMT sheets made of these materials. Later in the project, the top covers will be molded at FRAUNHOFER IWU by thermocompression.

The base plate (UC3.3), is developed by TECNALIA with the specifications provided by COMPOSITEC. TECNALIA is developing a thermoplastic RTM (Resin Transfer Molding) process to manufacture APA6 composites (anionic polyamide 6) reinforced with natural fibers for this use case.