FORTH: Coordinating BIOntier and pioneering 4D manufacturing

FORTH, as the coordinator of the BIOntier project and leader of WP9 (Management), ensures efficient coordination and adherence to quality and open science standards. Beyond coordination, FORTH leads key technical activities, including the integration of SSbD principles, safety and sustainability assessment of chemicals and materials, and optimization of surface treatment technologies, driving sustainability and scientific excellence across the consortium. In UC6 (High-Pressure Vessels for Water Filtration), the team focuses on developing recyclable, lightweight solutions for high-pressure water filtration applications, integrating its expertise in 4D hybrid printing and sustainable material engineering. The team combines expertise in materials science, photonics, and 4D printing to develop advanced bio-based composites and innovative manufacturing methods.

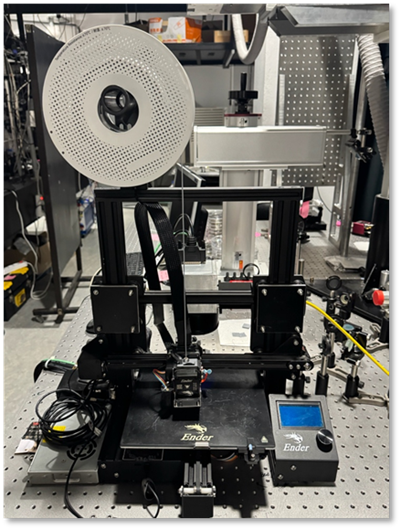

In (UC6), FORTH develops recyclable and lightweight bio-composite vessels using hemp-based PLA and its in situ 4D hybrid printing system. The redesigned sealing heads, created in collaboration with IRIS, eliminate metal inserts to enhance recyclability and performance.

Project Update

FORTH is currently upgrading its 4D hybrid printing system, replacing the Bowden extruder with a direct extruder to achieve more precise control, faster retractions, improved reliability with flexible materials, and a smoother surface finish. Additionally, a new printer motherboard enables faster processing, quieter operation, and smoother printing quality, significantly boosting speed and overall system performance.

Figure 1: In situ 4D hybrid printing system