FRAUNHOFER : develop, process and assess bio-based composites along the product life cycle

The Fraunhofer Society is the largest organization for applied science in Europe and is involved in BIOntier with four (ICT, LBF, IWU, CBP) of its 75 institutes. Fraunhofer is involved in all WP and all project phases in BIOntier, but especially involved in UC3, battery housing.

Fraunhofer is leading numerous tasks in BIOntier in the fields of circularity, additive and compound development, composite processing and testing. Furthermore, Fraunhofer is leading WP 7 (Life-Cycle, End-of-Life, and Sustainability Assessment) with a special focus on Life Cycle Assessment of the Use Cases and is Quality and Risk manager of BIOntier.

In BIOntier, Fraunhofer aims to upscale the processing of lignin to a usable basis for additives. This includes providing lignin and cellulose from pilot-scale production. See Picture below. © Fraunhofer IGB

In WP3, Fraunhofer develops additives and compounds (see picture below © Fraunhofer LBF) with fire retardant properties made from biobased raw materials.

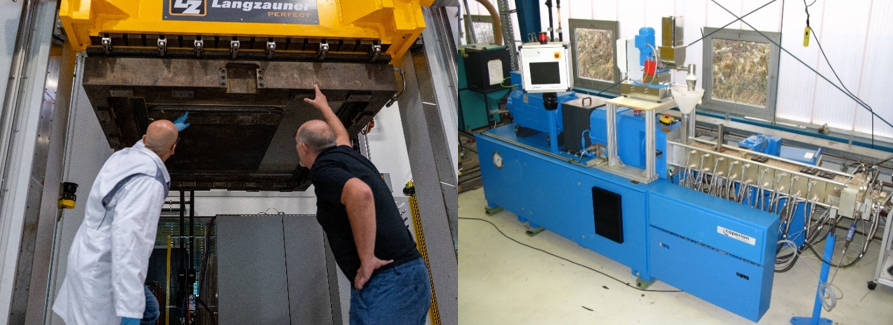

Fraunhofer is working to improve recycling techniques for biobased composites across different industries and enhance the processability of these biobased compounds and composites. Pictures below shows the compounder on the left (© Fraunhofer ICT) and the press used for the project on the right (©Fraunhofer IWU).

To demonstrate the applicability of the materials for selected applications, their properties will be tested at a material and demonstrator level. To improve circularity, components will be redesigned. The picture below shows the mechanical pre-processing and recycling lab (©Fraunhofer ICT).

An important aspect of this work is also the further development of methodologies to assess and communicate the environmental impact of the developed biobased materials and processes, with the goal of suggesting improvements already during the project phase and ensure a fair comparison of bio- and fossil based materials.

Fraunhofer is aiming to apply bio-based materials in areas under high mechanical and environmental impacts (thermal, moist, UV,…) and provide solutions to bridge the application gap for biobased composites in industrial products.